NASA researcher Julia Cline demonstrates that the impact of digital image correlation in mechanics is out of this world

From automobiles to aerospace, and every industry in between, digital image correlation (DIC) is changing the landscape of mechanics. When talking with Dr. Julia Cline from NASA Langley Research Center, it becomes obvious just how invaluable DIC is in the advancement of understanding material behavior. Cline, who received her MS and PhD in Aerospace Engineering from the University of Texas at Arlington, jokes that she lives by the motto “speckle everything,” referencing the practice of using speckle patterns to show contrast and gain various metrological data. Cline states that “DIC is a game-changing experimental mechanics technique that can provide greater insight into the mechanical behavior of materials and structures than traditional point-wise measurement techniques.”

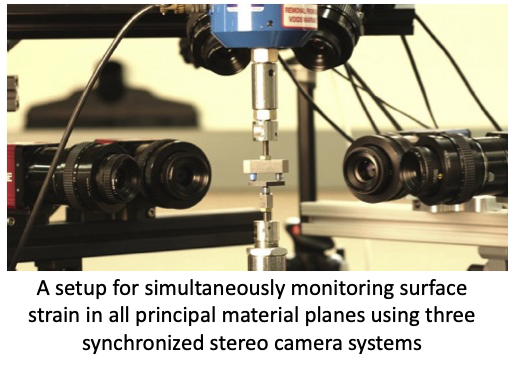

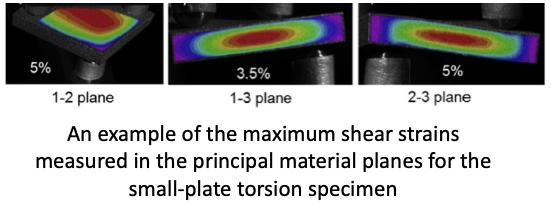

Cline’s extensive work in aerospace, that utilizes DIC, emphasizes her point. While working on her doctoral dissertation under the guidance of Dr. Andrew Makeev at UTA, she helped develop an experimental configuration using three synchronized, stereovision DIC systems to measure non-linear shear strains on three principal material planes of a carbon-epoxy composite small-plate specimen. The finite element-based material stress-strain constitutive relationship they developed, based on these DIC measurements, advanced their ability to measure 3D material properties, resulting in a first-of-its-kind method for measuring shear strain.

Dr. Cline has touched countless areas of the aerospace world during her career, including work in reentry heat shields, rotorcraft composites, and, currently, in-space assembly architectures and space nuclear propulsion.

Dr. Cline is also an active member of the International Digital Image Correlation Society (iDICs), serving as a board member. When asked about her motivation to serve on the board, Cline explained that she “[loves] the mission of iDICs and the goal of making DIC measurements as ubiquitous as conventional measurement techniques through standardization, certification, and education.” She helps carry out this mission by chairing the Technical Committee’s Council. Cline also noted the value in iDICs membership, and how it “[plays] a huge role in connecting [digital image correlation] enthusiasts all over the world by providing a network of academics, government researchers, and industry partners,” while also offering “opportunities for information sharing and training.” Cline explains that “iDICS provides training opportunities for those that want to become certified DIC users and learn advanced techniques,” while also providing industry partners “an enthusiastic group of consumers to showcase new developments [and] understand what is needed by the community, where gaps exist in current technologies, and to get creative juices flowing for further product development.” iDICs also offers members the ability to become DIC certified, enhancing a person’s professional credibility. “It’s a tangible benchmark and is proof you know what you’re doing because you’ve passed the certification exam developed by experts in the field.” As Cline’s work demonstrates, the uses of DIC in various fields are endless; from investigating axial strains on carbon-carbon composites at elevated temperatures, to using laser confocal microscopes to measure the deformation of a single polyethylene fiber less than 12micro-m in diameter. There’s no doubt that the future of digital image correlation is bright. As Cline states: “iDICs can push more universal acceptance of DIC as a validated method through standardization, certification, and education.”

Dr. Cline will, no doubt, continue finding innovative and ground breaking uses for digital image correlation, maybe one day even letting us see digital image correlation used in space!

Images from reference: Seon, Makeev, Cline and Shonkwiler, 2015, Assessing 3D shear stress-strain properties of composites using Digital Image Correlation and finite element analysis based optimization, Composites Science and Technology, vol. 117, pp. 371-378.